Auxiliary Equipment

Full-process Adaptation

Compatible with global mainstream packaging machine brands, seamlessly docking with existing production lines.

Intelligent Efficiency Enhancement

AI algorithms optimize operating efficiency, reducing the failure rate to less than 0.5%.

Flexible Customization

Supports modular design, and quickly delivers non-standard customization solutions within 7 days.

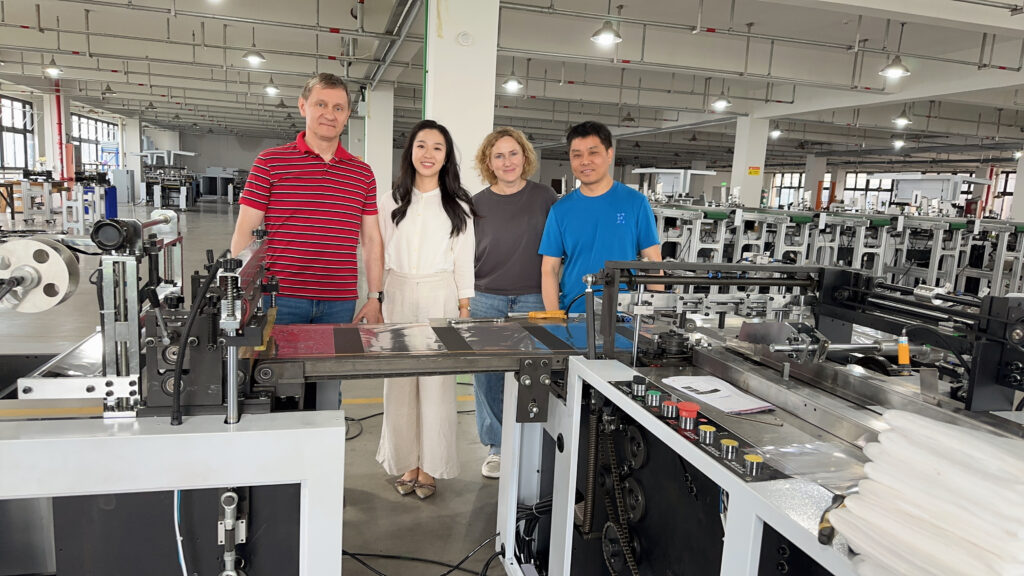

Our Supplier

Auxiliary Machine for Packaging and Filling

Bowl Elevator

- Equipped 304 stainless steel and 1.4L food grade PP hopper

- Widely used in the quantitative transportation of food, medicine, grain and small bag materials.

- Single Capacity:1.4L

- Conveying Capacity:2.5m³/h

- Ensures steady conveying of nuts, snacks, and granular products without spillage.

- Intelligent Speed Control

- Low Maintenance Design

Multihead Weigher

- Widely used for weighing granular products in pipelining operation

- Weigh Range: 5 – 5000g

- Max. Speed: 65 – 120bags/min

- Accuracy: ±0.1 – 2.0

- Weigh Bucket: 0.5L-5L

- Increases productivity and reduces product waste

- Ensures quick and accurate multi-point weighing

- Reduces labor costs and time in the packaging process

- Customizable for different product types and sizes

Stainless Steel Platform

- Durable, high-quality stainless steel construction

- L*W*H: 2000mm*2000mm*2000mm

- Resistant to corrosion and wear, ideal for food and pharmaceutical applications

- Easy to clean and maintain

- Provides a strong, stable base for various machines

- Designed to support heavy loads and ensure safety during operations

Liquid Filling Machine

- Suitable for liquid product, such as liquid detergent, shampoo,sauce,juice, honey and cleaning liquid product.

- Filling speed:6-30bags/min

- Filling volume:30-5000ml

- High-precision filling for liquids, ensuring consistent volume

- Can handle a wide range of liquid viscosities

- Features adjustable settings for different bottle sizes

- Ensures minimal spillage and waste

- Fast filling speed to increase production efficiency

Auger Filler

- Ideal for packing milk powder, rice flour, nutritious food, solid drink, food additive, monosodium glutamate, condiment, glucose, dyestuff, essence, spice and other materials.

- Filling Speed:40-120bags/min

- Package Weight:10-5000g

- Weight:160kg

- Packing Accuracy:≤ ±1%(≤ 100g) ≤ ±0.5%(100 – 1000g)

- Automatic volume adjustment via touchscreen

- Dust-Resistant Structure

Metal Detector Machine

- Accurately detects metal contaminants in food and products

- Ensures compliance with safety standards and regulations

- Increases product safety and quality control

- Easy to integrate into production lines

- Offers customizable sensitivity settings for various products

Lifting Conveyor

- Widths: 400mm/340mm(belt)

- Lifting capacity: 4000L/hour

- Material:304 stainless steel

- Features adjustable speed control for optimal performance

- Can handle various types of products and materials

- Designed for high durability and low maintenance

- Saves space while increasing overall production efficiency

- Optional: PVC chain plate, PVC/PU belt, 304# stainless steel mesh chain, 304# stainless steel chain plate, etc

Z Type Bucket Elevator

- Ideal for vertical transport of bulk materials like grain, powder, and granular products

- Space-saving Z-shaped design maximizes production efficiency

- Conveying Ability: 3 – 6m³/h

- Highness of Lifting: 3 – 10m

- Speed of Lifting: 0 – 17m/minute

- Carbon steel plastic-spray or stainless steel.

- Prevents spillage and product loss during transport

- Features smooth and reliable operation

Finished Package Conveyor

- Designed for efficient transport of finished packages in production lines

- Ensures smooth and continuous flow of packages without delays

- Can be customized to handle various package sizes and weights

- Features high durability to withstand heavy loads and long operational hours

- Easy to maintain and integrate into existing production systems

- Reduces manual handling, improving overall production efficiency and reducing labor costs

Application

Our Authority Certificates

Why Customer Choose us

Facts

Thanks to years of hands-on experience working directly in industries, our sector managers have a deep understanding of how their sector works.

MIssion

We ensure that every minute detail is looked into while manufacturing even the smallest product. Our focus is 100% on customer needs and satisfaction.

Industry experience

Here you will get a personalised engineering service, professional guidance, up-to-date information on the latest knowledge and the possibility to improve your designs.

Testimonials

Get appointment with our 1 vs 1 Specialist

Getting the right equipment for the right money!

Email:info@lintyco.my

Tel:+8613868827095